Bolt Tensioning & Torquing and Joint Management System

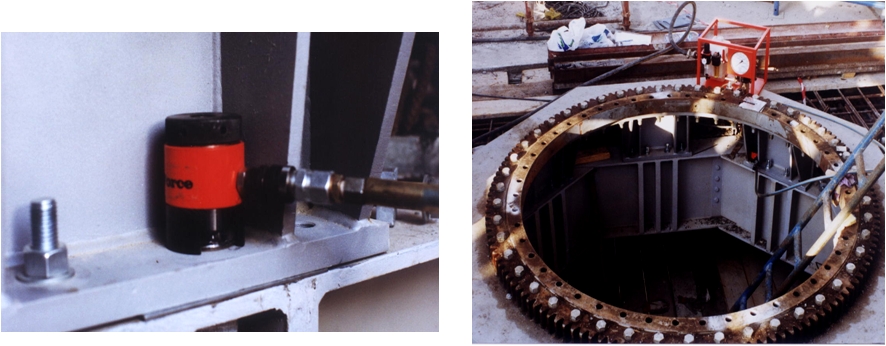

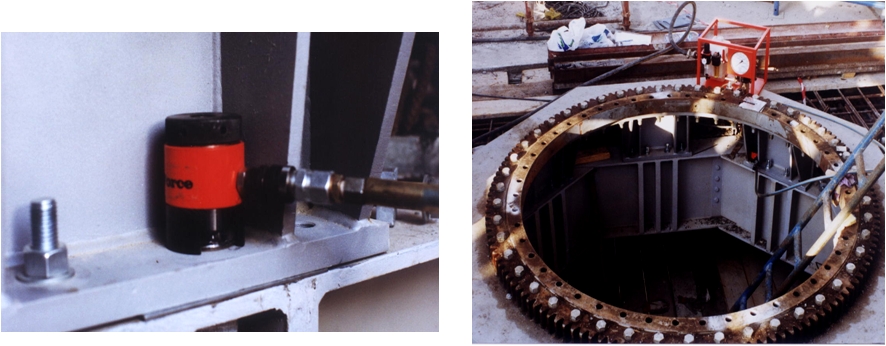

The Total Reliable Solutions key personals managed the projects carried out Hydraulic Bolt torquing and tensioning requirements of the entire project, complete in schedule, maintained complete data base of the joints, ensuring joint integrity and Achieved Zero leak in major construction projects

The Total Reliable Solutions key personals managed the projects carried out Hydraulic Bolt torquing and tensioning requirements of the entire project, complete in schedule, maintained complete data base of the joints, ensuring joint integrity and Achieved Zero leak in major construction projects

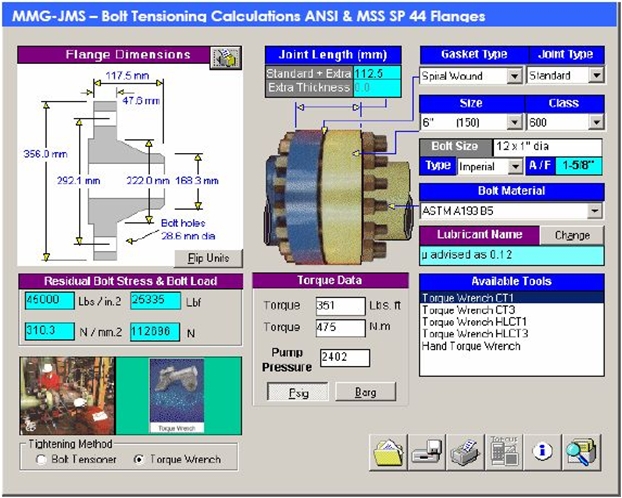

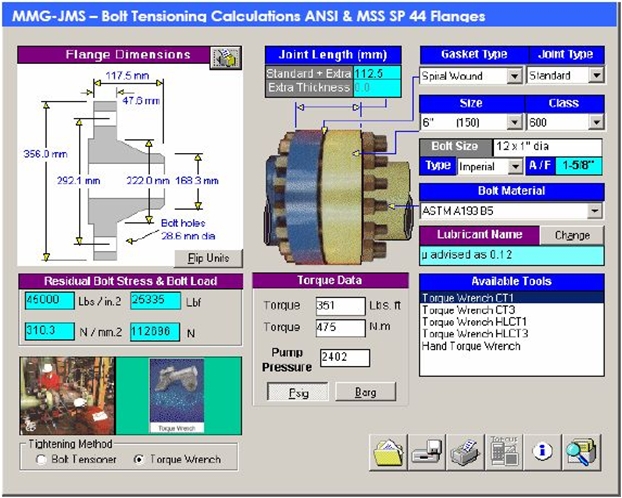

To successfully tighten a joint there are many pieces of information we need. If we can provide these easily and effectively to a competent person, using fit for purpose calibrated equipment, on correctly designed and specified joint, then we will be leak free.

How will it help ensure joint integrity?

- The BoltRight programme will calculate the correct torque or tension figures based on the input of the joint details.

- The programme will work in both Imperial and Metric options.

- It will identify and recommend the most suitable Hi-Force tooling for completing the job based upon the tightening values calculated.

- It will also generate a tightening procedure for the joint.

Hi Force Torquing and tensioning has been approved by a number of major operators as their bolt calculation standard. Whilst Bolt Right carries out a calculation for the joint JMS takes this further by enabling the data to be permanently stored against a particular joint.

JMS Core Package

The JMS Core package includes a Database,. The System can be supplied as a single user package or as a multi user system installed on a Network. The JMS Core package will provide users with the following benefits and services.

The JMS Core package includes a Database,. The System can be supplied as a single user package or as a multi user system installed on a Network. The JMS Core package will provide users with the following benefits and services.

- Recording and storing all data relating to controlled tightening of critical joints.

- System to control and calculate joint tightening data either by the functionality of Hi Force Bolt Right or for special joints by recording the calculation source.

- Source of controlled Joint Tightening procedures.

- Work pack management system for controlling and recording work on critical Joints.

- Inspection within the work pack manager allows recording of alignment, gasket info, flange surface and other inspection of the joint.

- System to record and manage Exceptions and Non Standard Joints.

- Means of recording leaks and the actions taken.

A key benefit of implementing JMS is that whenever a joint is worked on, all of the previous history and experience of that joint is available, allowing any particular requirements of the joint to be taken into account proactively prior to joint assembly and tightening.

In addition to the Core JMS package to allow tailoring to Customer needs and budgets various modules and functionality can be added

The Total Reliable Solutions key personals managed the projects carried out Hydraulic Bolt torquing and tensioning requirements of the entire project, complete in schedule, maintained complete data base of the joints, ensuring joint integrity and Achieved Zero leak in major construction projects

The Total Reliable Solutions key personals managed the projects carried out Hydraulic Bolt torquing and tensioning requirements of the entire project, complete in schedule, maintained complete data base of the joints, ensuring joint integrity and Achieved Zero leak in major construction projects The JMS Core package includes a Database,. The System can be supplied as a single user package or as a multi user system installed on a Network. The JMS Core package will provide users with the following benefits and services.

The JMS Core package includes a Database,. The System can be supplied as a single user package or as a multi user system installed on a Network. The JMS Core package will provide users with the following benefits and services.